Preventing Site Downtime: 3D Printed Spare Parts for Construction Machinery

Preventing Site Downtime: 3D Printed Spare Parts for Construction Machinery

In the construction industry, the old adage “Time is Money” is literally true. A single broken excavator or a malfunction in a concrete pump can bring an entire project to a standstill. When deadlines are tight and penalties for delay are high, waiting weeks for a replacement part to arrive from overseas is simply not an option.

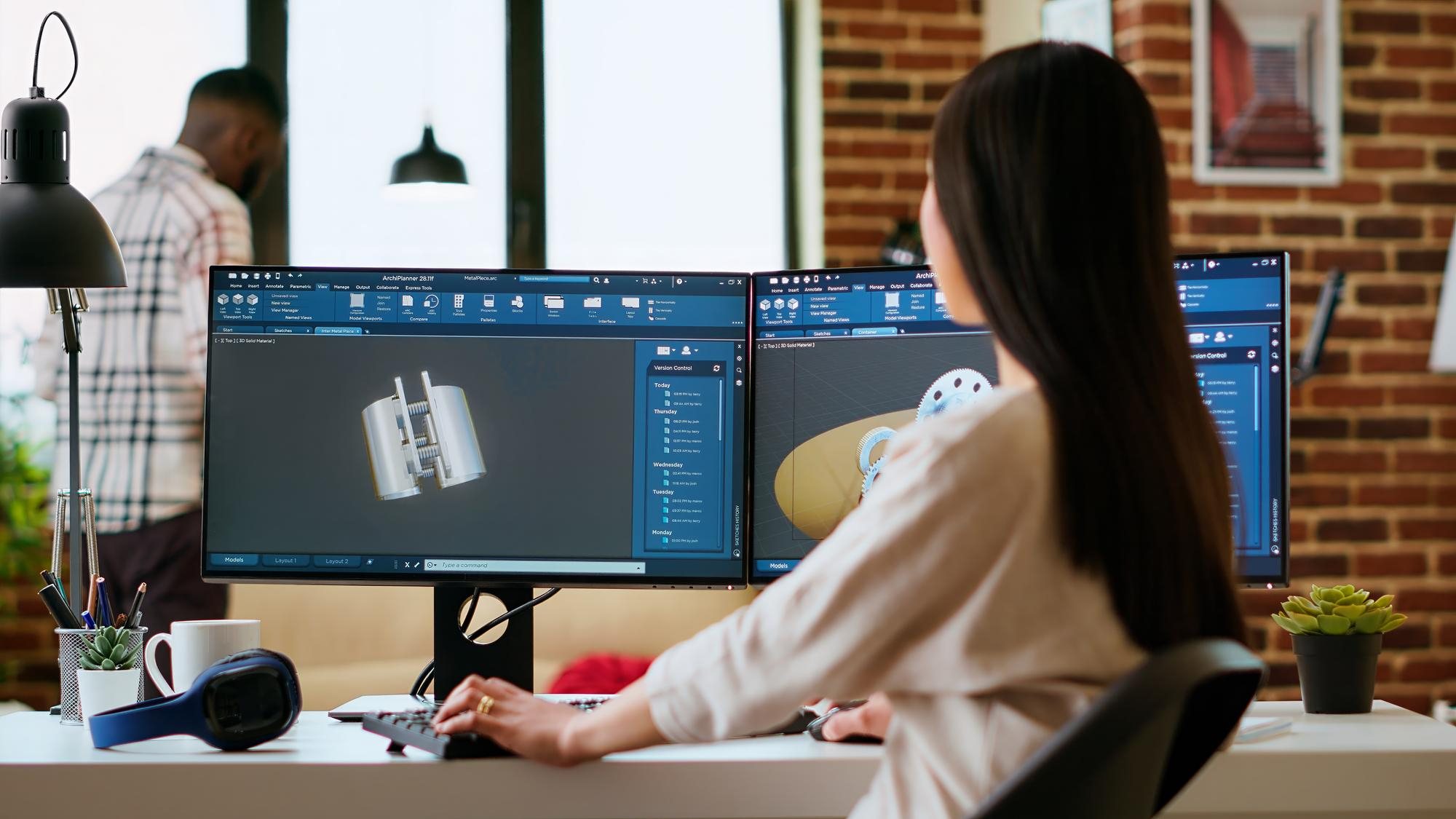

This is where Industrial 3D Solutions (Additive Manufacturing) is revolutionizing the construction sector. Instead of relying on fragile global supply chains, forward-thinking project managers are turning to on-demand manufacturing to keep their sites running.

The Cost of “Waiting” in Construction

Traditional spare part procurement is often a logistical nightmare, especially for projects in remote locations in Africa or developing regions in Europe. The process usually involves:

- Identifying the broken part number.

- Ordering from an OEM (Original Equipment Manufacturer) abroad.

- Waiting for international shipping and customs clearance.

- Result: Days or weeks of expensive machine downtime.

The Solution: Digital Inventory and On-Demand Printing

Industrial 3D printing changes the game by replacing physical warehouses with “Digital Inventories.” Instead of storing thousands of spare parts that might never be used, the digital design files (CAD) are stored in a cloud. When a part breaks, it can be printed immediately.

What Can Be Produced?

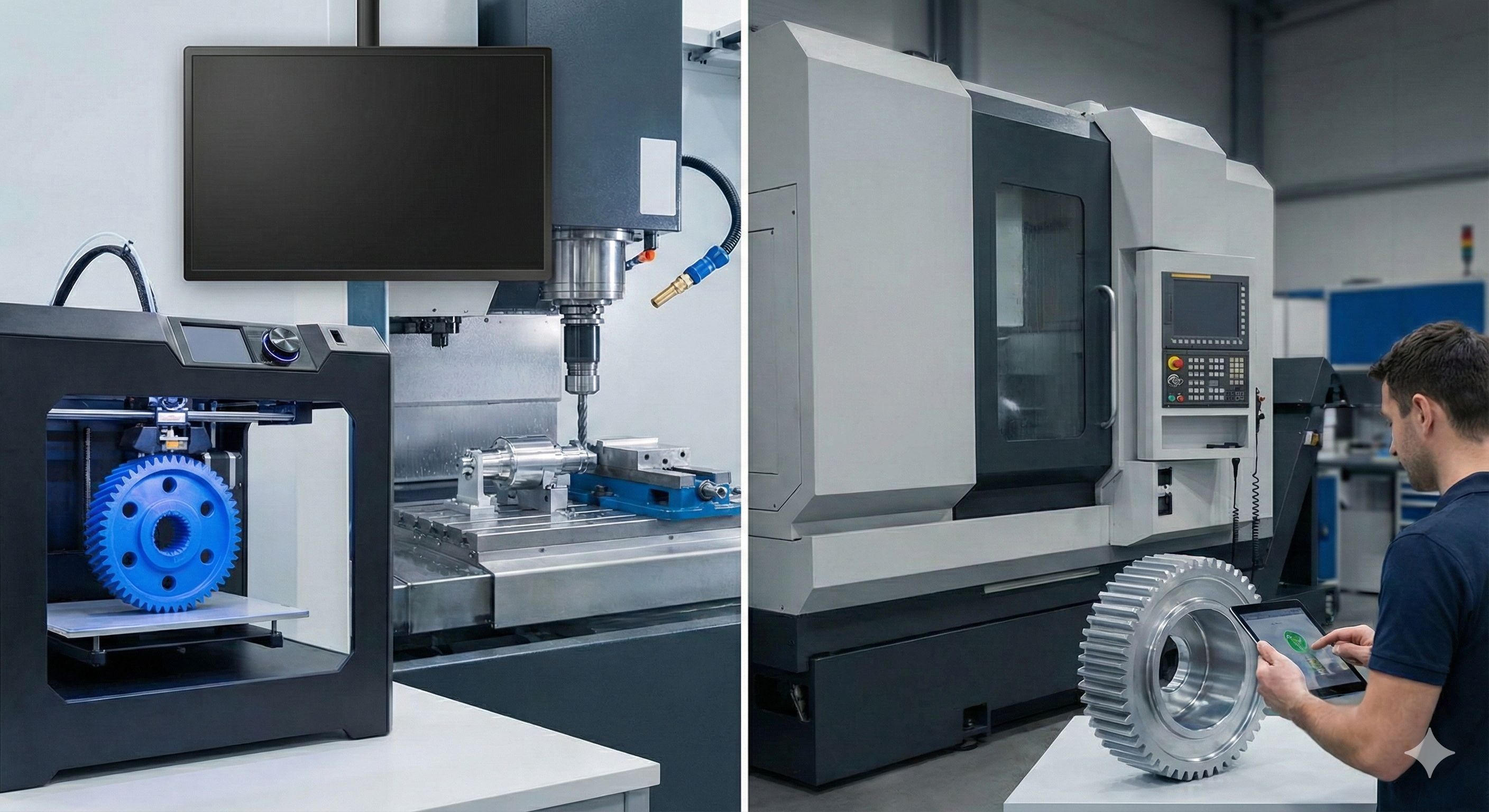

While not every engine block can be printed (yet), a surprising number of critical components can be manufactured using high-strength polymers or sintered metals:

Obsolete Parts

Parts for older machinery that are no longer manufactured by the OEM can be reverse-engineered (scanned) and reprinted.

Temporary Fixes

Printing a temporary polymer bracket or handle to keep the machine operational until the original metal part arrives.

Custom Tooling

Creating specific jigs and fixtures to help mechanics repair complex machinery on-site faster.

3 Key Benefits for Project Managers

1. Speed (Lead Time Reduction)

What used to take 3 weeks can now be done in 24-48 hours. Tradentis’s Industrial 3D Solutions allow for the rapid production of functional parts, getting your machinery back to work in record time.

2. Logistics and Cost Efficiency

Shipping a heavy metal part via air freight is expensive. Sending a digital file to a local 3D printing hub (or printing it at our facility in Turkey and shipping via express courier) is often significantly cheaper and faster.

3. Extended Lifespan of Equipment

Don’t scrap a million-dollar crane just because a small, plastic connector is broken. 3D printing extends the lifecycle of your heavy equipment assets.

How Tradentis Supports Your Site

At Tradentis, we bridge the gap between heavy industry and advanced technology. We support construction projects not only by supplying the Heavy Equipment itself but also by providing the Industrial 3D Services needed to maintain them.

Whether you need a hard-to-find spare part reverse-engineered or a rapid prototype for a custom site solution, our engineering team in Turkey is ready to support your operations in Africa and Europe.

Don’t Let a Broken Part Stop Your Project

Contact us today to learn more about our spare part sourcing and 3D manufacturing capabilities.