Industrial 3D Solutions

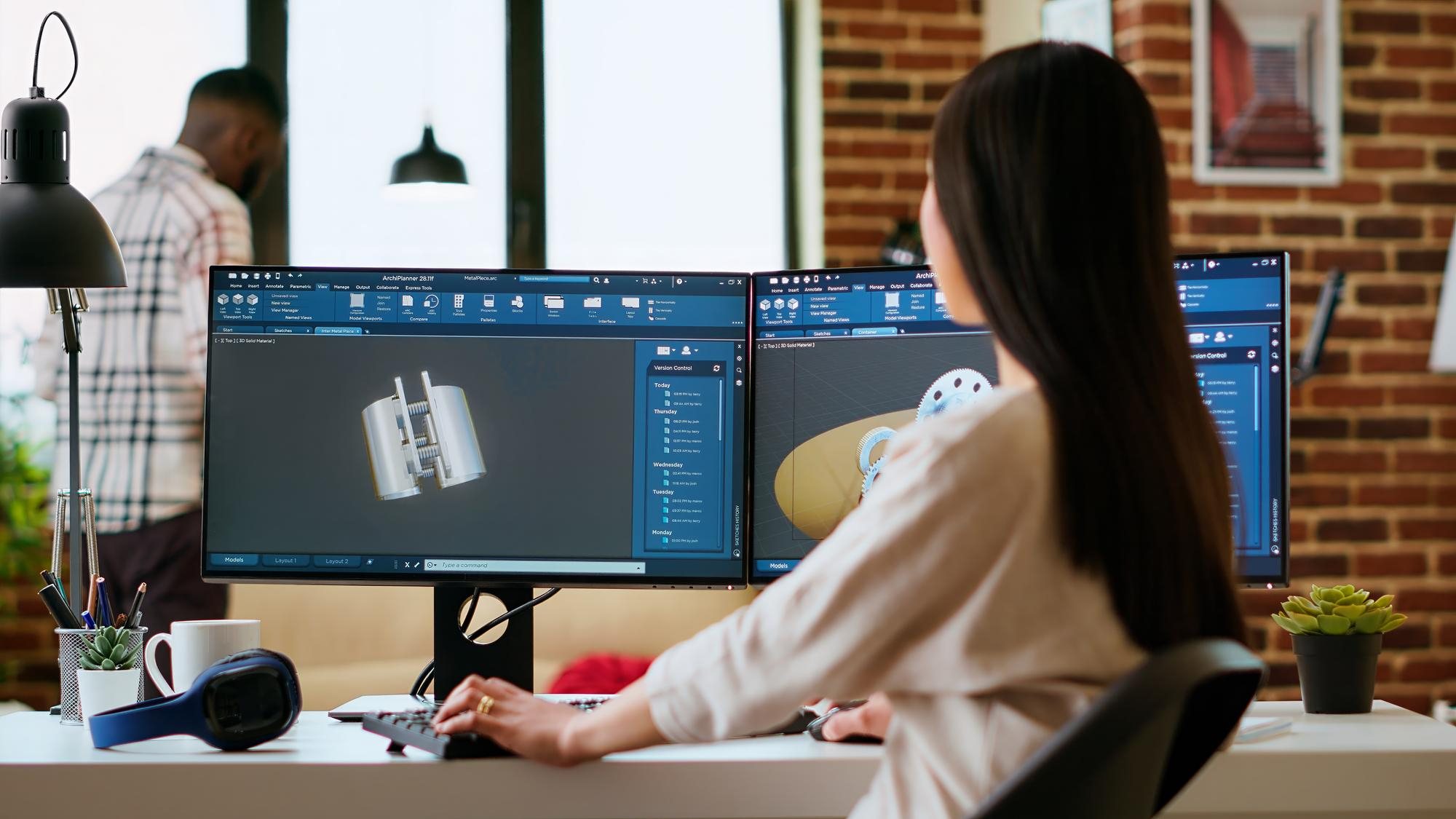

Industrial 3D Solutions: Accelerating Innovation and Manufacturing Efficiency

The competitive industrial landscape rewards businesses that can innovate rapidly and adapt to market demands with flexibility. Industrial 3D solutions (additive manufacturing) are specifically engineered to transform complex digital designs into physical reality for sectors ranging from automotive and aerospace to construction and medical fields. Rapid prototyping, geometric complexity, functional precision, and supply chain agility are the fundamental characteristics of our advanced 3D manufacturing services.

Integrating 3D technology into your workflow bridges the gap between concept and production, eliminating the need for expensive tooling and drastically reducing time-to-market. Choosing the right industrial 3D partner empowers your business to produce functional end-use parts and customized components on demand, securing a critical competitive advantage in the global market.

INDUSTRIAL 3D SOLUTION APPLICATION AREAS

Industrial 3D solutions enhance innovation and efficiency across various sectors:

Industrial Manufacturing

Supports production lines with functional parts, custom tooling, jigs, and fixtures, reducing downtime and optimizing workflow.

Construction and Infrastructure

Enables rapid production of complex architectural models, structural nodes, and on-site spare parts integration with BIM projects.

Automotive and Aerospace

Produces lightweight, high-strength components and prototypes for aerodynamic testing, ensuring fuel efficiency and performance.

Healthcare and Medical

Facilitates the creation of patient-specific guides, prosthetics, and anatomical models for pre-surgical planning with biocompatible materials.

R&D and Innovation Labs

Accelerates the product development cycle through rapid prototyping, allowing for iterative testing and immediate design validation.

Consumer Goods and Electronics

Enables mass customization and low-volume production of casings, brackets, and intricate components without expensive molds.

KEY FEATURES OF INDUSTRIAL 3D SOLUTIONS

Rapid Prototyping

Transforms digital designs into physical objects in hours, drastically reducing time-to-market for new products.

On-Demand Manufacturing

Eliminates the need for physical inventory by allowing parts to be printed only when needed (Digital Inventory)

Design Freedom (Geometric Complexity)

Manufactures complex geometries and internal lattice structures that are impossible to produce with traditional CNC or molding methods.

Waste Reduction

Additive manufacturing builds parts layer by layer, using only the necessary material, significantly reducing industrial waste compared to subtractive methods.

Material Versatility

Supports a wide range of industrial materials, from high-performance thermoplastics and resins to industrial-grade metals.

Cost-Efficiency for Short Runs

Removes the need for expensive tooling and molds, making low-volume production and one-off custom parts economically viable.

INDUSTRIAL 3D PRODUCT GROUPS

Functional End-Use Parts

Durable, production-grade components ready for real-world use in machinery, vehicles, and infrastructure.

Architectural Scale Models

Detailed and precise 3D models for urban planning, building visualization, and client presentations in the construction sector.

Visual and Functional Prototypes

High-fidelity models for aesthetic verification and functional testing before mass production commitment.

Spare Parts on Demand

Replacement parts for obsolete machinery or urgent maintenance needs, produced quickly to prevent operational stoppages.

Jigs, Fixtures, and Tooling

Custom manufacturing aids that improve assembly line efficiency, safety, and precision on the factory floor.

Low-Volume Production Series

Bridge manufacturing solutions for market testing or limited edition product runs without high initial investment.

Advantages of Choosing Industrial 3D Solutions

- Accelerated product development cycles and faster time-to-market

- Reduction in warehousing costs through digital inventory

- Innovation in design without manufacturing constraints

- Sustainable manufacturing with minimal material waste

- Ability to customize products for specific client needs without extra cost

Accelerate Your Innovation with Tradentis 3D Investing in industrial 3D solutions not only speeds up your R&D process but also revolutionizes your supply chain. Tradentis empowers your business to produce complex parts locally, reduce tooling costs, and respond instantly to market demands. Transform your ideas into precision reality with our advanced additive manufacturing capabilities.